Pyrogasification

Pyrogasification is one of the four complementary sectors supported by GRTgaz for producing renewable and low-carbon gas. This innovative technology adds dry solid waste (wood waste, solid recovered fuels, etc.) to the spectrum of waste that can be recovered as renewable and low-carbon energy. Pyrogasification forms part of the regional virtuous circular economy. It strengthens regional energy sovereignty and contributes to the decarbonisation of uses.

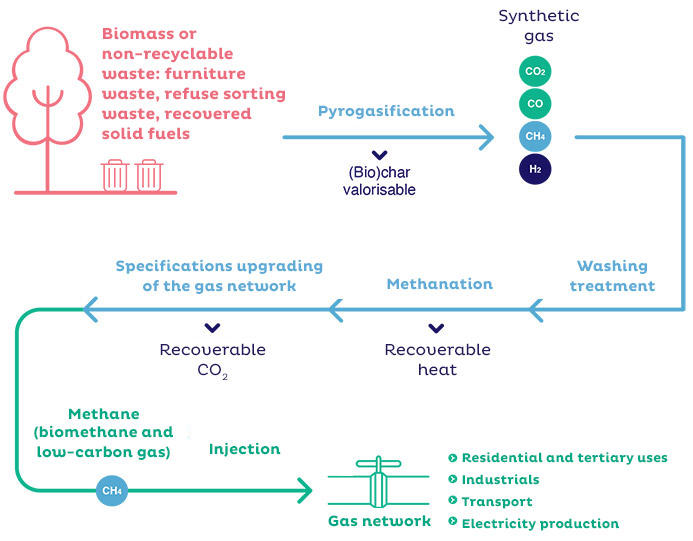

Pyrogasification: how it works in 4 simple steps

Recovering waste that is poorly recycled or non-recyclable as renewable and low-carbon gas

Pyrogasification is a high-temperature thermochemical process for converting solid residues and waste into gas for injection into the existing gas networks. It is aimed at inputs that are poorly recovered or non-recovered, and offers a virtuous alternative that supplements traditional waste treatment sectors.

A wide range of waste and residues are processed.

How does pyrogasification work?

Residues and solid waste are heated at high temperatures (between 800-1,500°C) with little or no oxygen, then converted into renewable and low-carbon gases.

Gas produced in this way is directly injectable. It can be stored and accessed at any time via the existing networks.

What benefits does pyrogasification offer?

The gas produced by pyrogasification is 100% substitutable for natural gas in all its uses, without the need to modify the customers’ facilities (mobility, industry, use of raw materials, heat production, etc.).

Pyrogasification has numerous benefits:

- Energy:

- Production of a methane-rich gas that can be injected directly into the networks;

- Non-intermittent production of storable, available energy;

- High energy efficiency (from 65-85%)

- Waste:

- A local solution for recovering waste that is poorly recycled or non-recyclable, operating as closely as possible to the deposits. This reduces the environmental impact of the mass transport of solid waste and its burial or incineration;

- Environment and health:

- A drastic reduction in the carbon footprint (few or no air pollutants, particles, dust, etc.).

- Socio-economic:

- A regional and local circular economy (local production, local consumption, creation of jobs that are not at risk of relocation);

- Energy sovereignty for the regions.

How does pyrogasification fit into the circular economy?

Pyrogasification recovers residues and dry waste whose non-recyclable status means that they are currently burned, buried or exported. It provides new answers to the problems encountered by the regions (local authorities, manufacturers, waste managers, etc.), offering a way to recycle their waste locally and decarbonise their activities. It gives a boost to the industrial base and creates jobs that cannot be outsourced.

“France’s dynamic pyrogasification sector is ready to take off, bringing together numerous public and private stakeholders of all sizes spanning the whole value chain, from producers to consumers. The year 2023 saw a landmark step, with the public authorities’ anticipated launch of a Call for Projects to support the rollout of the first industrial and commercial units”Clotilde Villermaux

Pyrogasification Project Manager

Where is the pyrogasification sector expanding in France and Europe?

Where are these pyrogasification sites producing injectable gas located?

There are several industrial projects and demonstrators in France and in Europe. They demonstrate the technical feasibility of the process and the quality of the gas produced from pyrogasification for injection into the networks.

In Sweden, for more than a year, the GoBiGas industrial demonstrator in Gothenburg has injected biomethane from wood pyrogasification into the networks (power: 20 MWCH₄ i.e. 90,000 tonnes/year of wood). In England, a commercial facility is being commissioned in Swindon. In France, the GAYA semi-industrial demonstrator has confirmed the efficacy of pyrogasification for solid recovered fuel (SRF) waste.

What is the outlook for its deployment in France?

The pyrogasification sector is entering the industrialisation phase in France – a pioneering country for the structuring of an organised sector producing low-carbon renewable gas (biomethane) from pyrogasification for injection into the networks.

In 2022, GRTgaz led the “Pyrogasification for Injection” Call for Expressions of Interest (CEI) launched by the CSF, New Energy Systems. With 49 projects identified, the CEI confirmed the existence of a French ecosystem centred on the pyrogasification sector, which is ready to industrialise based on a network of committed stakeholders and specific projects.

New projects have since joined those first identified during the CEI, showing the sector’s positive momentum. As well as producing biomethane from waste of renewable origin, these projects will also produce low-carbon gas thanks to the recent establishment of a regulatory framework for the recovery of non-renewable waste. Following the announcement in 2023 of a production support mechanism, the estimated deployment date for the first industrial and commercial units is now 2026-2027.

Figures from the “Pyrogasification for Injection” CEI launched by GRTgaz under the aegis of the CSF NSE in 2022:

- 49 projects

- Regional facilities of various sizes enabling the production of 200 to 2,000 m3/h of renewable and low-carbon gas

- Production potential of 4.1 TWh/year of renewable and low-carbon gas

- Energy recovery per facility of 10,000 to 70,000 tonnes of waste per year (i.e. up to 1.5 million tonnes in total).

These facilities are compatible with the levels of local waste production, and can hence support the emergence of a circular economy in the regions. For example, an average plant producing 1,000 m3/h of renewable and low-carbon gas can heat 1,500 households or power 400 buses, coaches or trucks per year.

Pyrogasification projects producing renewable and low-carbon gas for injection into the gas networks:

>> Online map and indicators in the ODRÉ website

2030 targets:

- Recovery of 3 million tonnes of waste per year

- Injection of 6 TWh of renewable and low-carbon gases per year (2050 target: 90 TWh)

- CO₂ emissions reduced by 1 million tonnes/year

Publications

Useful links: a video and a podcast

To go further

Renewable and low-carbon gases